Super-HIPS®

Do you know? HIPS is a piece of jade. According to the feedback of more than 20 customers in recent years, hips with skill patch package is not only competent for ABS, but also for ASA. In this year of "breaking a penny into two halves", HIPS is a proper potential stock!

Today, let's use data and application cases to see which more expensive plastics can be defeated by the upgraded HIPS?

1. Replace ABS

ABS is comparable to the king of appliance applications. Almost every appliance has ABS applications from the shell to the internal parts. Hips and ABS have the same shrinkage, so without modifying the injection mold, you can directly use the mold of the previous ABS parts to produce HIPS parts.

Therefore, with the sharp rise in the price of ABS raw materials, HIPS has a significantly greater price advantage, but the strength and toughness of ordinary HIPS are lower than ABS. Therefore, ordinary HIPS cannot completely replace ABS. Therefore, HIPS can also achieve the same application effect as ABS by strengthening the strength and toughness of HIPS. At present, there is a relatively mature general ABS flat replacement scheme in the market. Like Kumho-sunny Super-HIPS® Super tough hips n501; Its notch impact strength is greater than 20kj/m2, significantly higher than hips (10-14), and the same as ordinary ABS. The impact cracking resistance is better than that of ABS.

Not yet, if you think it is common for HIPS to replace ordinary ABS. Take a look at the following applications. Use hips instead of high impact ABS. Yes, when the shortest board of hips is made up, there will be no ABS!

(Super) Typical applications of high toughness HIPS :

Commonly used washing machine shell.

Air conditioner tongue, pressing plate and air outlet.

Refrigerator liner, door end cover, door shelf, etc.

2. Replace ASA

In some outdoor and semi outdoor applications, the shell parts with ABS or conventional HIPS will change color and become brittle after long-term use, affecting the appearance, and the cost of using weather resistant ASA will increase significantly.

At this time, using "weather resistant enhanced HIPS" is a highly cost-effective choice. I remember when ABS students went crazy last year, Xiao Bian had Super-HIPS® on hand,The super weather resistant hips n505 has helped customers achieve COSTDOWN index with no danger. The customer's product is a new energy charging pile, which has serious yellowing after long-term use. Let's take a look at the experimental comparison after 1008h irradiation of UV accelerated aging: the long-term anti yellowing ability of N505 is significantly better than ABS, close to ASA, and combined with the cost advantage of HIPS itself, it is undoubtedly the most preferred.

Typical applications of weather resistant HIPS:

Air conditioner, charging pile, outdoor camera shell;

The trunk and front guard of the electric motorcycle.

3. As a special material for preventing abnormal sound

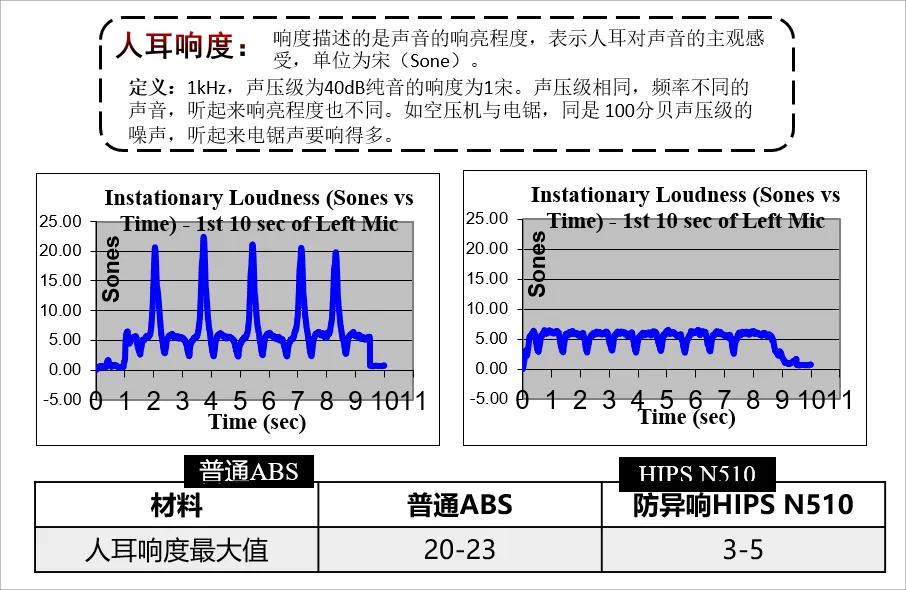

Household appliances, especially air conditioners, will produce abnormal noise when they expand and contract during work, and plastic parts rub. It has always been the hardest hit area of customer complaints. Old fans must know that there is a set of popular "anti abnormal sound materials" in Jinhu Rili industry, which has been widely used by mainstream manufacturers at present. The solution is to increase the damping of the material to absorb the vibration energy generated by friction through the material itself, so as to reduce the friction noise. It not only reduces the production labor cost of sticking cotton cloth, but also reduces the cost of after-sales door-to-door service.

However, the sharp rise in raw materials last year forced our customers to find a more cost-effective solution. Guess what, it takes no effort to find him thousands of times: compared with other substrates, the human ear loudness of anti abnormal noise hips is lower! Let's take a look at the experimental data:

Typical applications of anti abnormal noise HIPS:

It has been applied in many domestic head air-conditioning manufacturers to hang up the inner frame of air-conditioning. In addition, high-end computer keyboards and car interiors are mass produced.

4. As chemical resistant material

In recent years, with the recurrence of the epidemic and the increase of disinfection and sterilization scenes,

This puts forward higher requirements for the "chemical resistance" of many traditional materials. During the use of many products, the plastic shell may be in contact with various disinfectants, sunscreen, etc., which may damage the materials and need to improve the chemical resistance.

Typical applications of chemical resistant HIPS:

Medical instrument shell, electric vehicle shell.

To be serious, the competition in the stock era has begun from the moment of improving the "effectiveness" of material selection!

From all aspects of practical application, HIPS has become the "king of cost performance". How to improve the maximum potential of HIPS while controlling costs. Get twice the result with half the effort? Kumho-sunny's Super-HIPS® must be one for you. Welcome to put forward your needs and troubles. Let's work together to solve problems.

Contact Us