COLORFUL-IN®

COLORFUL-IN® Application background of spray free aesthetic plastic

In order to meet the needs of consumers for beauty, post-processing means such as spraying are usually used to achieve the beautiful appearance of plastic products. However, spraying not only pollutes the environment, but also has many problems such as many production links, high production costs and low design freedom.

With the improvement of national requirements for environmental protection, the spraying industry has been more and more regulated, and the demand for spray free aesthetic plastics in the market is showing a strong upward trend. However, most spray free plastics on the market are simply realized by adding color masterbatch and dyeing granulation. Due to the lack of design of material color and texture, it is inevitable to give people a sense of cheapness and fail to achieve aesthetic effects. "Spray free aesthetic plastic" echoes distinctive products.

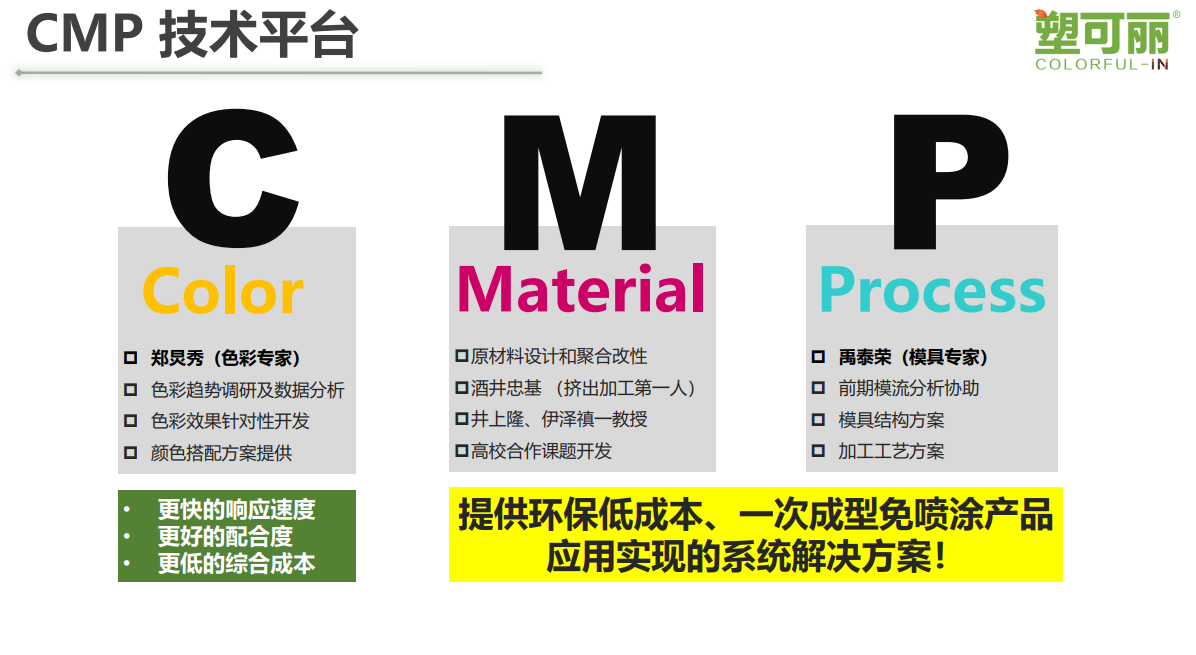

COLORFUL-IN® is a spray free aesthetic plastic that can be injected and extruded at one time. Through the integration of C (color), m (raw material technology) and P (molding process), it can better solve the problems of flow marks and welding lines encountered in spray free plastics, and greatly improve the appearance and texture of plastic products.

COLORFUL-IN® Application value of spray free aesthetic plastic

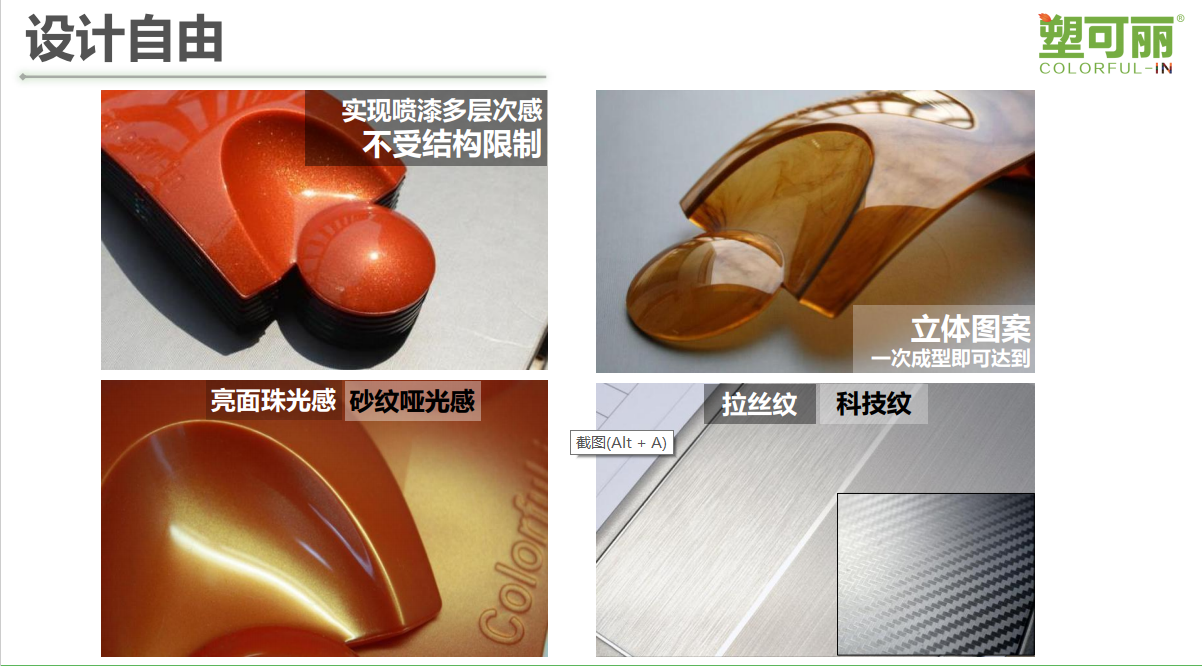

While making the plastic material aesthetic, it takes into account the advantages of one-time molding, spray free, more environmental protection and convenience. It relieves all kinds of restrictions in the production process, brings designers a high degree of design freedom, and can realize many visual creativity that cannot be achieved by spraying. Enhance aesthetic feeling: bright and transparent, bright and layered; It is more environmentally friendly to realize the visual creativity that spraying cannot achieve: zero emission of air pollution; It is more convenient for workers without potential health hazards: one-time molding, simplified process; High design freedom.

COLORFUL-IN® Spray free aesthetic plastic professional services

COLORFUL-IN® The proposed CMP system solution, through the integration of C (color), m (raw material technology) and P (molding process), not only effectively solves the industrial problems such as flow marks and welding lines in the spray free technology, but also pays attention to the creativity of material texture and texture, and better shows the plastic aesthetics.

COLORFUL-IN® Application Guide:

Kumho-sunny has a color development center composed of expert color consultants and professional color design engineers. At the same time, on the basis of strong R & D and application capabilities, it introduces Autodesk Moldflow software to optimize the structural design according to the characteristics of plastic materials and product requirements, and organically integrates the color, material performance requirements and post-processing process of products. In 2008, it established the CMP department, Better cooperate with customers in product development; In order to meet the performance requirements of customers on different products, Jinhu Rili has developed plastic Cori materials with a variety of substrates to give customers better choices.

Contact Us