Digital Sentry

Product: Super-HIPS® flame retardant PC/ABS HAC8250NH for spray paint, which has excellent paint performance;

The weather-resistant flame-retardant PC/ASA HSC7079NH has significantly better weather-resistant than the current mainstream flame-retardant PC/ABS.

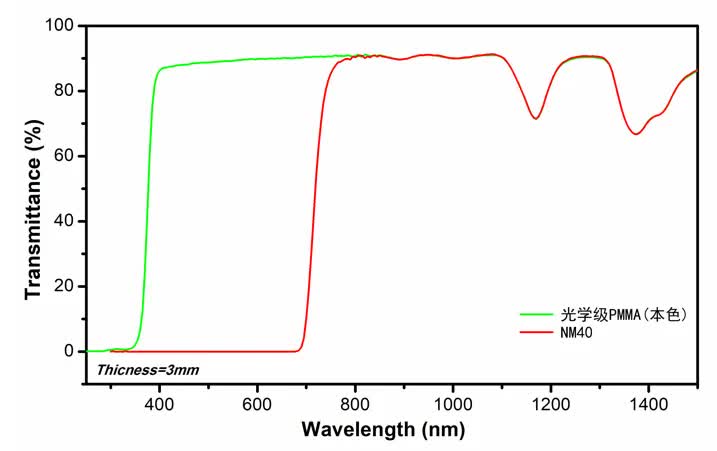

Super-HIPS® PC N840, PMMA NM40. The improved NM40 has an infrared transmittance of more than 90% and a visible light transmittance of 0, which has excellent weather resistance and can be used as a special material for infrared detection protective covers.

Have you seen it? The way of using it is similar to the way we used to pay by face-scanning, which can simultaneously test your body temperature and nucleic acid report. It has a wide range of installation methods and is widely used in public places, residential areas, shopping malls, schools and other entrances.

Thus it can be seen that the basic core of the digital sentry is actually: the display screen with the embedded detector. As a material supplier who has served several corporate champions in the field of security monitoring, the editor will dismantle and explain which materials are the most applicable for digital sentry.

List of commonly used materials for digital sentry

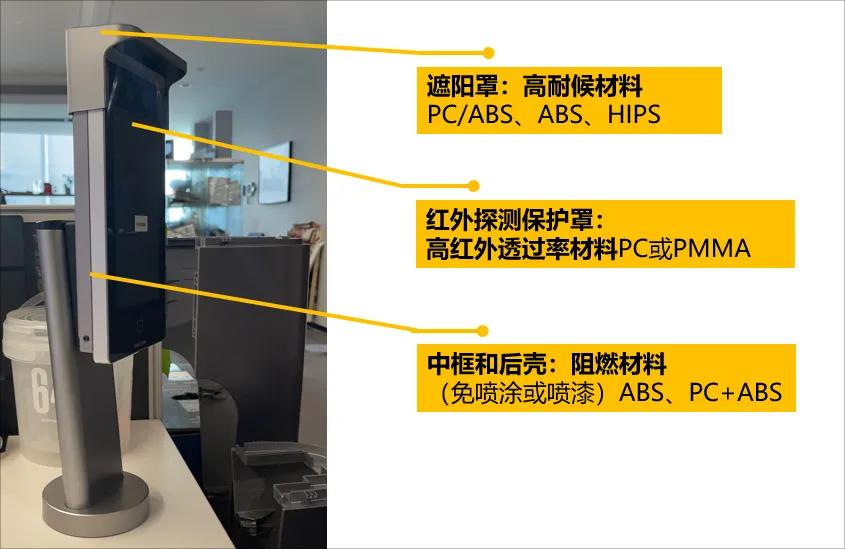

If we turn a digital sentry over, its basic structure from top to bottom is as follows:

1. Sunshade

The sunshade is just a popular saying. Generally, in outdoor scenes, it will be designed with a convex image of the sunshade, while the indoor design is embedded. The fundamental purpose is to protect the body temperature detector below (internal), as the umbrella of the entire device, the weather resistance requirements of this material are inevitable. Since weather-resistant plastic will also be mentioned below, let's focus on another function of it: beauty.

• In public places, in order to cater to the public aesthetic appearance, the vast majority of digital sentries use a metal casing similar to the iPad.

[Material selection suggestion]:

At present, under the trend of replacing steel with plastic, most monitoring instruments give up metal and focus on plastic. However, adopting "plastic + spray painting" is not only costly, but also does not meet environmental protection requirements. Solid-color weather-resistant plastics in white or black look inflexible, and spray coating-free aesthetic plastics are a good choice in comparison.

The editor recommends the aesthetic COLORFUL-IN®, whose appearance is characterized by a bright silver metallic texture. Compared with the painted parts, it cannot be said that it looks alike, it is exactly the same. The appearance of the material is metallic silver after one-time processing, which is more environmentally friendly and more efficient than spraying. At present, the mainstream materials range from weather-resistant ABS, PC/ABS to weather-resistant HIPS, and even PP, all of which can achieve metallic effects. If you don't believe that, please take a look at the appearance of the mass production product below:

2. Infrared detection protection cover

The infrared detection protection cover is the most crucial part of the external material of the digital sentry, which is related to the normal use and service life of the product!

In general, the material should meet the following requirements:

• In order not to interfere with infrared detection as much as possible, the infrared transmittance of the material is required to reach more than 90%;

• In order to cover the infrared fill light, the material is required to be opaque to visible light;

• For outdoor use, the material is required to have weather resistance.

[Material selection suggestion]:

In some head security monitoring product manufacturers, editor has a material that has been tried and tested repeatedly, that is, the special material for the Super-HIPS® infrared detection protective cover: PC N840, and PMMA NM40. Taking the latter as an example, comparing with optical grade PMMA, the improved NM40 has an infrared transmittance of more than 90%, a visible light transmittance of 0, and has excellent weather resistance. With the test of so many predecessors, it is naturally seamless to apply to the digital sentries.

3. Middle frame and shell

On account of the shell material directly covers the PCB board, coupled with factors such as uneven heat dissipation outdoors in summer, it is very easy to cause short-circuit fires. Therefore, the housing material needs to have excellent flame retardant properties. At present, there are two main options for the selection of shell materials:

1. Spray paint on the surface of flame retardant materials. However, it should be noted that because the mainstream PC/ABS flame retardants are easy to cause material cracking, the solvent of the paint may aggravate the material cracking;

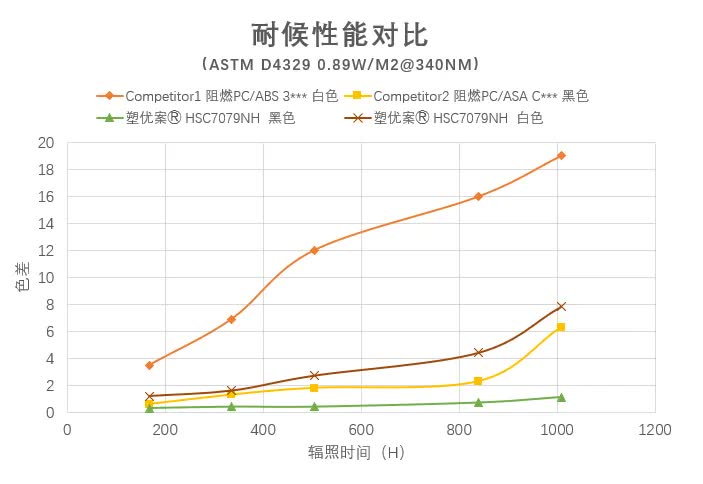

2. Directly select spray coating-free weather-resistant and flame-retardant materials. Generally, flame retardant ABS can be selected, and some more expensive ones are PC/ABS and PC/ASA. However, due to the presence of flame retardants, the weather resistance of the above substrates with better weather resistance will be greatly weakened (such as many damaged new energy charging piles), and it is difficult to achieve both "flame resistance" and "weather resistance".

[Material selection suggestion]:

In response to the above two major issues, the editor has been repeatedly asked by customers. Fortunately, our R&D engineers are excellent, not only have we developed a flame retardant PC/ABS HAC8250NH for Super-HIPS® spray painting, which has excellent painting performance; but also developed a weather-resistant flame-retardant PC/ASA HSC7079NH, the weather resistance which is significantly better than the current mainstream flame retardant PC/ABS, which greatly avoids the safety and quality problems caused by the "Yellow brittleness" of the shell. Let us pull together our peers and speak with test data:

Contact Us